XY6000 Batch Control System

Overview

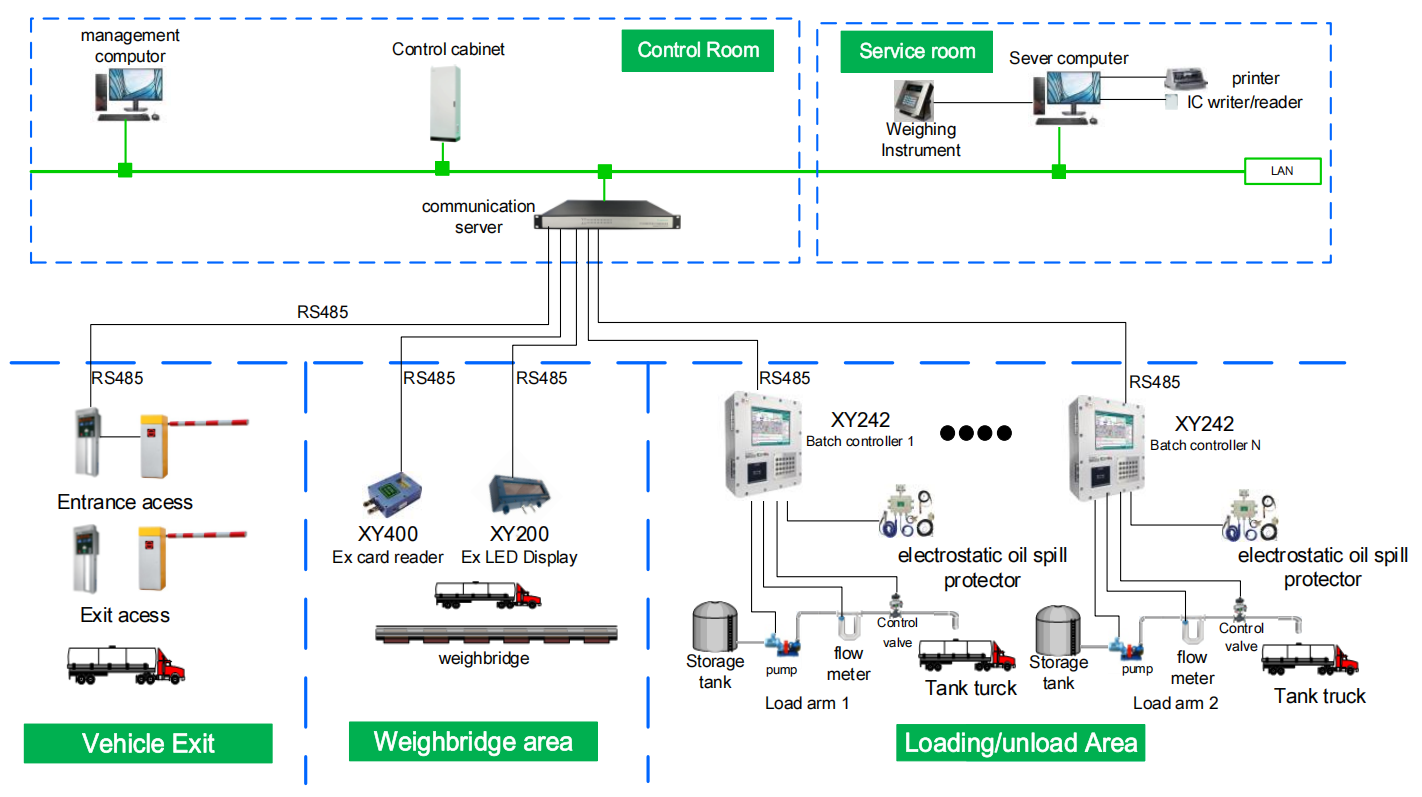

Composition

+System consists of computers and a set of software, communication servers, weighbridges (optional), batch controllers, electric/pneumatic control valves, electrostatic/oil spill protectors, volumetric/mass flow meters, explosion-proof screen displays and other equipment.

Loading /unloading process can be operated by the computer issuing instructions to batch controllers and also can be operated directly on batch controllers. Each batch controller collects data and signal such as quantity, flow rate, temperature, electrostatic/oil spill alarm signal, valve feedback and etc., to control valves opening/closing and pumps starting/stopping, then realize batch controlling. Comparing the weight by weighbridge and the quantity by batch controller, System completes the oil delivery task.

Architecture and Functions

+Control Room

- One set of engineer computer for loading/unloading management, and connecting with other system;

- One set of service computer for information key-in, card issuance, document printing and other operations;

- One set of card reader and management software for “all-in-one” card, paperless functions;

- One set of control cabinet for communicating and power supplying with batch controllers.

Loading/unloading Platform

- Batch controller automatically controls loading/unloading process;

- Volumetric or mass flow meter calculates loading/unloading quantity; Accuracy is determined according to need;

- Control valve ensures loading/unloading process smooth;

- Electrostatic oil spill protector ensures loading/unloading process safe.

Weighbridge (configured as needed)

- Collect the weight of loaded/unloaded tank truck, and if exceeding the standard;

- Compare the weight by weighbridge and the quantity by batch controller, and occur alarm if exceeding the standard.

Topology diagram

+

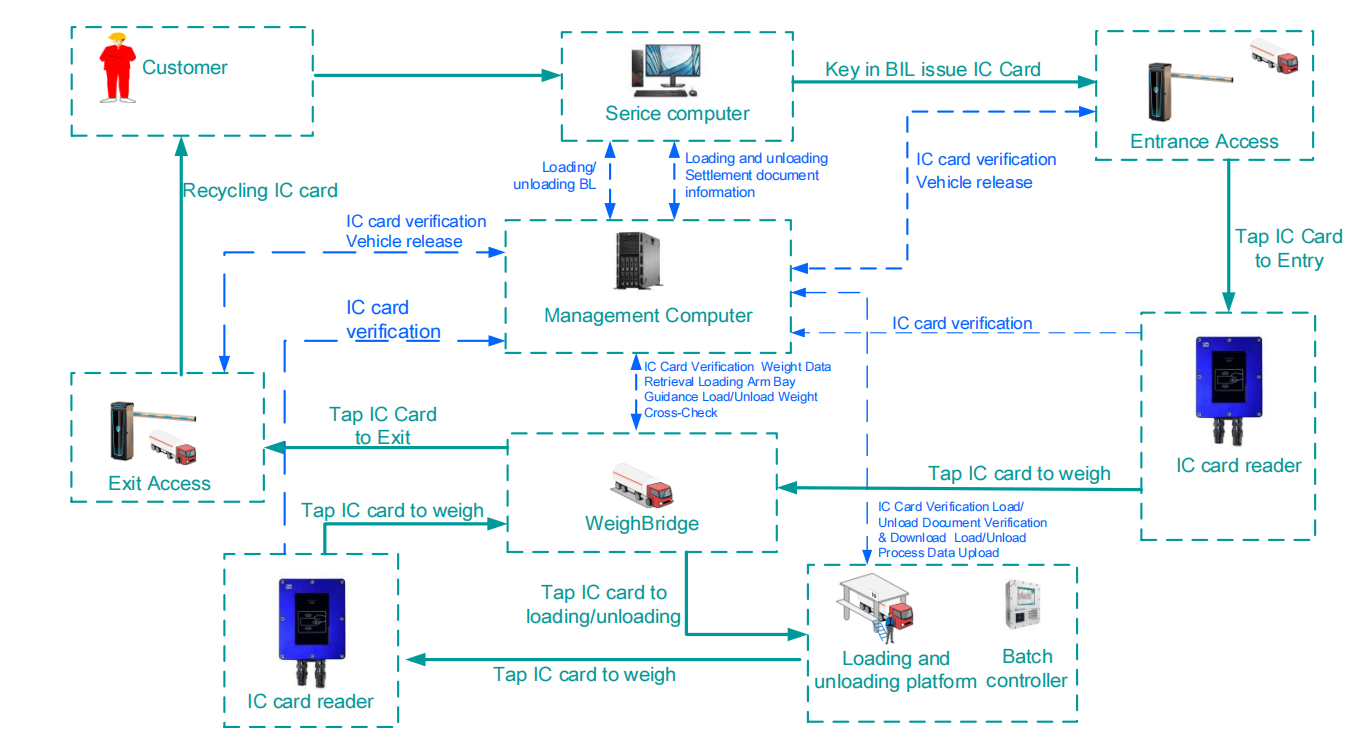

Flow Chart

+

Equipment introduction

+XY242 Batch Controller

XY242 batch controller is an explosion-proof operation panel that integrates an advanced programmable logic controller and a button-type human-machine interface. With advanced control algorithms, it has the characteristics of high control accuracy, reliable performance. By providing standard communication protocol (MODBUS.RTU), it is connected with management computers, weighbridges, flow meters, thermometers, electrostatic/oil spill protectors, control valves, etc., to constitute a complete batch control system.

Basic features

- True color 10-inch TFT high-brightness screen

- Real-time display of mass/volume, flow rate, temperature, density, and time

- Online or offline working mode

- Operator password, system administrator password setting

- Anti-static and oil spill protection, abnormal flow rate alarm and other interlocking protection functions

- Precise control to solenoid valve, multi-stage control valve, regulating valve, etc.

- Pump and valve logic control

- Overloading alarm

- Detective function of operator/driver on-site (optional)

- API standard temperature compensation function (optional)

- Self-diagnosis test

- Surge protection

Basic parameters

- Explosion-proof mark: ATEX: II 2G Ex db IIB+H2T6 Gb; IECEx: Ex db IIB+ H2T6 Gb

- Protection level: IP66

- Accuracy: ±1 pulse

- Power supply voltage: AC220V or AC110V

- Ambient temperature: -40~60℃

- Pulse signal input: Vp-p≥2V, frequency≤30KHz (standard: 2 channels; up to 4 channels )

- Digital signal input: for valve/pump, electrostatic/oil spill protectors feedback (standard:10DI; up to 16DI)

- Digital signal output: for pump control, valve control and others (standard: 8DO; up to 12DO)

- Analog signal input (4-20mA): for temperature, pressure, and valve feedback (standard: 2AI; up to 4AI)

- Analog signal output (4-20mA): for regulating valve control (standard: 1AO; up to 2AO)

- 1-RS485 communication bus: for PC

- 24-key Hall stainless steel buttons

- Recognizer type: IC card reader or QR code reader

XY400 Explosion-proof Card Reader

The XY400 explosion-proof IC card reader integrates electronic, network, explosion-proof, radio frequency identification and other technologies,to realize the information management of production processes such as card issuing, tank truck enter/leave recognizing, automatic loading/unloading operations, and weighbridge weighing, to ensure efficient and accurate information transmission and improve production efficiency and tank truck management.

Features

- Explosion-proof mark: ATEX: II 2G Ex db IIB+H2T6 Gb; IECEx: Ex db IIB+ H2T6 Gb

- Protection level: IP66

- Power supply voltage: DC24V

- Ambient temperature: -40~60℃

- Device working status display

- Automatically read card swipe data

- Cardholder account and file management

Software Functions

+

- Basis document management: information of storage-tanks, oil products, tank trucks, transport licenses, driver licenses and etc.;

- Monitoring function: real-time status display of platform, pumps/valves, electrostatic/oil spill protectors, all alarm signal and various parameters set such as safe flow rate, pulse equivalent, advanced-close volume, temperature and pressure limit and etc.;

- Service operation: information key-in and card issuing, remote unlocking, order cancellation, emergency delivery and etc.;

- Alarm management: any equipment failure or abnormal condition, system occurs an alarm and reminds the operator to handle, and automatically records the alarm signal;

- Data management: acquire and process real-time data of access, weighbridges, batch controllers in system, and store all loading/unloading records more than 3 years;

- Query function: according to different combination conditions to query loading records and generate reports;

- Operation protection function: by authority setting and password protection, each operator can only operate within authority to prevent unauthorized operating;

- Interface function: with a standard communication bus (MODBUS.RTU), system can connect with other systems such as DCS.

Contact Us

3F, Building B, Dingxin Technology Park, Honglang North 2nd Road, Bao'an District, Shenzhen, China

Follow Us

Copyright © 2025 Shenzhen Xuyong Industry Co., Ltd. All Rights reserved.